NEWS

Software News & Updates

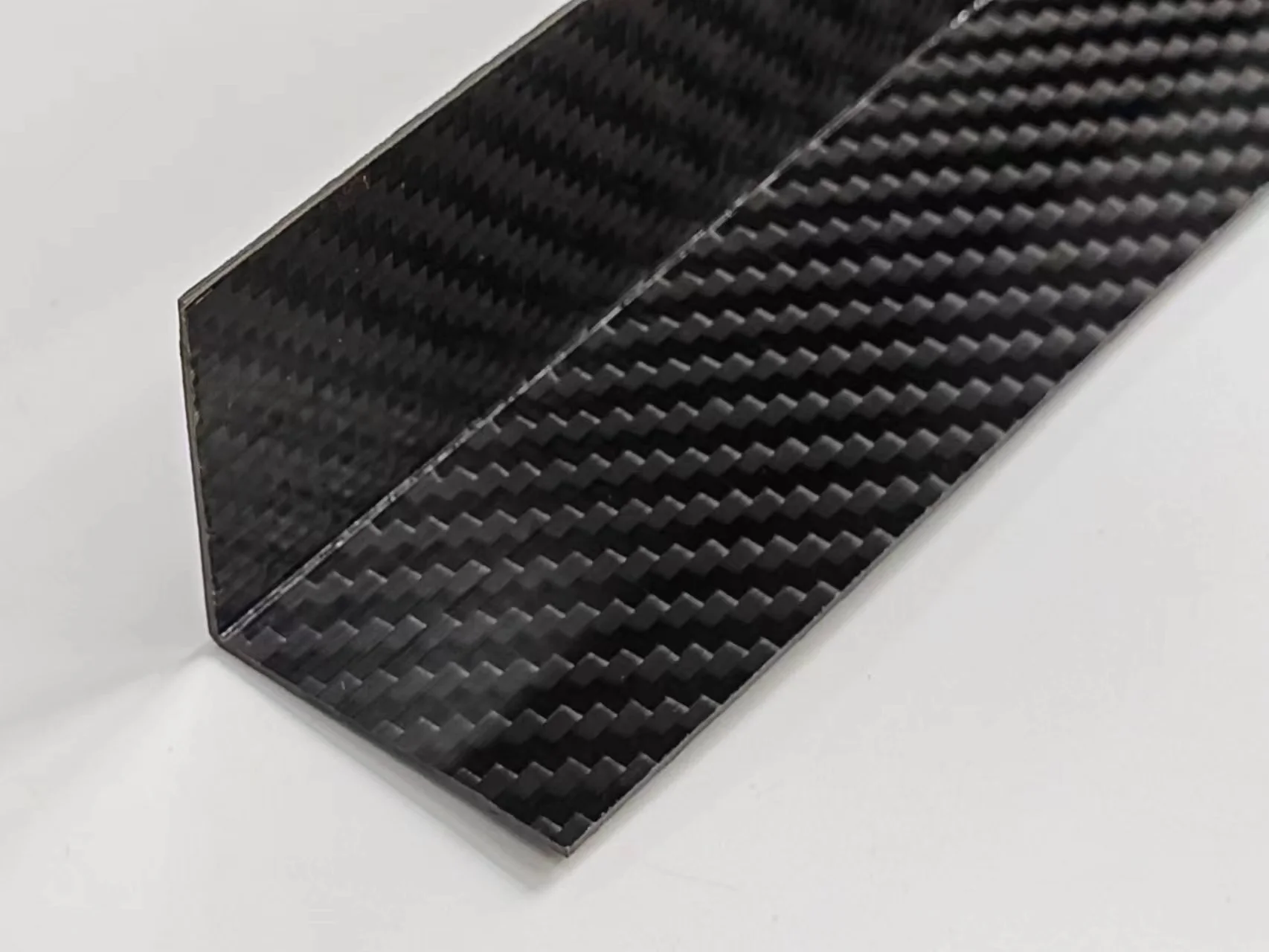

Cadfil

July 2025

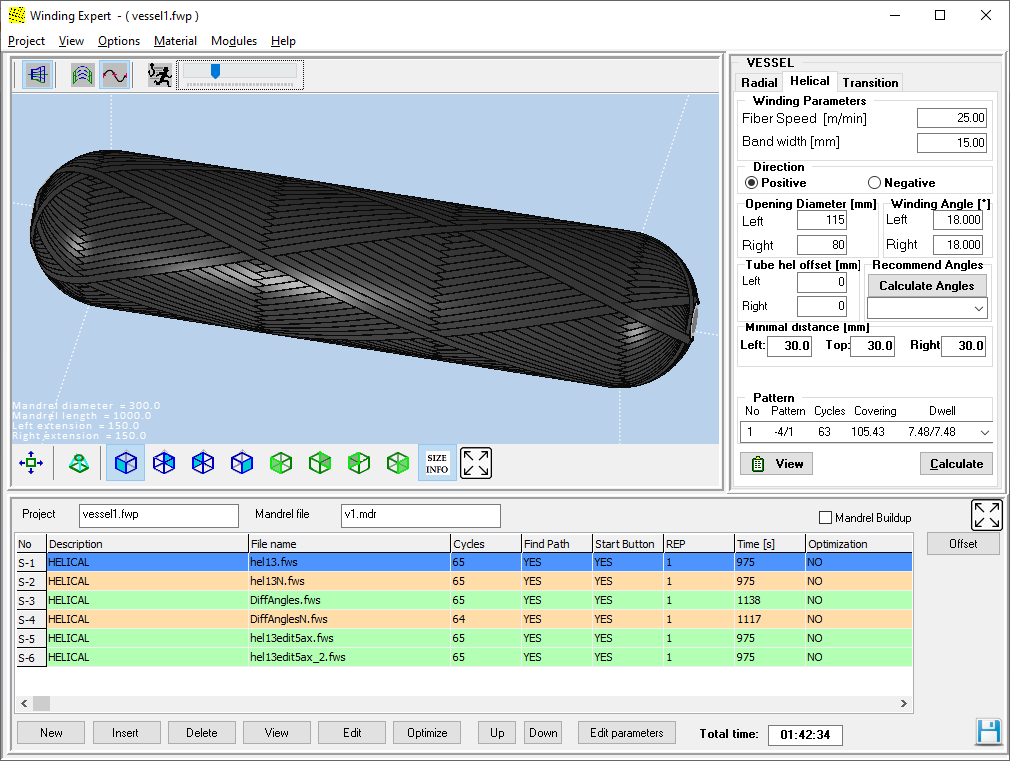

Software update V1.10

Taniq

October 2025

Software update v1.86

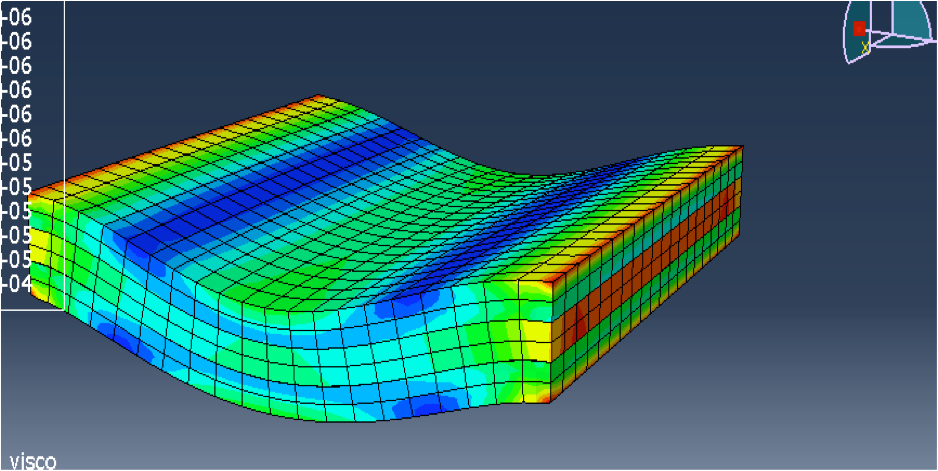

Cadfil

July 2025

September 2025: New Release of Cadfil V9.90

Taniq

July 2025

Software update V1.09